MTEC places importance on industrial standards by collaborating with various institutions. The implementation of these standards would help support the industrial sector and other agencies in the country to overcome trade barriers caused by standards-related measures.

Standards Developing Organizations: SDOs

The Innovative Rubber Manufacturing Research Group has been registered as Standards Developing Organizations (SDOs) in the advanced category, section 29: Rubber and rubber products, with the Thai Industrial Standards Institute (TISI), which became effective on July 1, 2020. The Innovative Rubber Manufacturing Research Group, therefore, is authorized to create a draft standard related to rubber and rubber products to propose to the Thai Industrial Standards Institute (TISI) to consider promulgating it as an industrial product standard of the country (TIS). Some international standards (ISO) have also been developed and amended by this research group.

During the Fiscal Year 2021, noted MTEC works that have been promulgated as standards are as follows:

- Thai Industrial Standards (TIS 2666-2563) of Rubber plucking fingers for poultry

Rubber plucking fingers for poultry are a key component of both circular and automatic plucker machines that pluck feathers from the poultry, such as chickens, ducks, and turkeys, as part of poultry processing. This standard specifies the physical characteristics and safety requirements of rubber plucking fingers for poultry in order to assure users of product quality.

• TIS 3052-2563 of Rubber railway level crossing panel

Most railway level crossing panels in Thailand are made of concrete but in foreign countries rubber is a preferred material. This is because rubber products will help distribute stress to the sleepers, thus reducing shock, vibration and sound and allowing cars to pass faster without slowing down. Currently, the State Railway of Thailand has been employing the rubber railway level crossing panels in some areas and domestic manufacturers are interested in its production. Since there has been no standards for the technical specification of the rubber railway level crossing panels, an establishment of this standard will, therefore, ensure product acceptance.

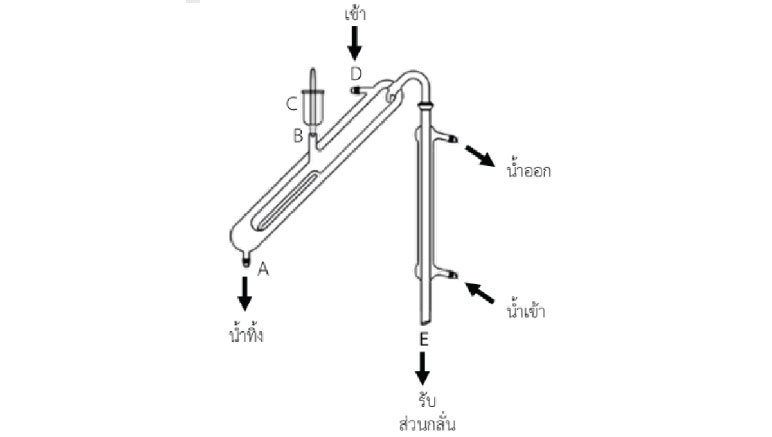

• ISO 506:2020 Rubber latex, natural, concentrate – Determination of volatile fatty acid number

Volatile fatty acid number (VFA Number) is a very important index that indicate the quality of the latex. The test method is based on the coagulation of the latex with ammonium sulfate solution and then the separation of serum into acid with sulfuric acid. The resulting serum is then distilled and used as substrate for the volatile acid from the distillation. The volatile fatty acid content was then titrated with barium hydroxide solution. Although the standard test methods are widely used around the world, there are certain technical flaws need to be solved. This standard has been developed to address such problems so that an improved testing method will be realized.

Participation in the process of establishing standards

Since MTEC researchers have expertise in various fields of materials technology, they are invited by various institutions to join technical committees and subcommittees on standardization, which is a vital step in enhancing the quality of products and the competitiveness of Thai entrepreneurs in international trade. MTEC researchers have participated as members of the following group:

• TIS 2623 Electrical power insulators Part 1 Test methods

The Ceramic and Glass Research Team of Ceramics and Construction Materials Research Group has participated in preparing the draft standard of the Electrical power insulators Part 1 Test methods, which is the standard that defines the test methods for the specific characteristics of insulators. The test method for a given electrical insulator is unique as specified by its associated standard so as to attain efficient, suitable and safe products for use in the country’s power distribution system.

MTEC engagement and commenting in the standards establishment process involves the cooperation between the government and private sectors. This undertaking helps all partners understand the trends in applications, types, inspection methods, and requirements for the use of various related products. The acquired knowledge gives a crucial guideline for quality control in manufacturing and product development for the insulator operators, as well as helps build confidence for the Electricity Generating Authority of Thailand to maintain the stability of the country’s energy system.