Research background

Siam Modified Starch Co., Ltd. has expertise in tapioca starch production. The company places importance on the problem of global climate change, as well as plastic waste contamination that affects creatures, environment, and society. The company, therefore, is interested in the concept of the BCG (Bio-Circular-Green Economy) and wanted to mitigate non-degradable plastic waste problems.

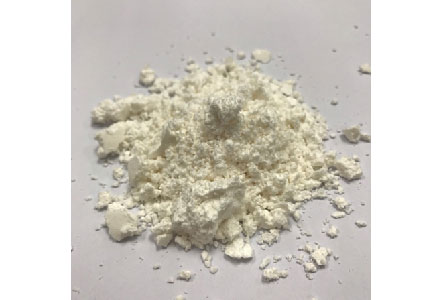

The company has cooperated with the Plastics Technology Research Team of MTEC in the development of biodegradable materials from tapioca starch since the research team has expertise in twin screw extrusion by designing the screws that can be melted and kneaded various polymer materials. Thus, a research project is initiated in order to develop the manufacturing process for the preparation of thermoplastic starch prototype (thermoplastic starch, TPS) with the twin screw extruder at the pilot scale.

The research team has employed an existing formula for a mixture of raw materials consisting of tapioca starch, water and plasticizer as a reference and then prepared a compound between thermoplastic starch and biodegradable polymer (TPS/biodegradable polymer) suitable for productions and various applications.

Research objectives

(1) To gain knowledge of thermoplastic starch production processes and to produce prototypes from a pilot-scale twin screw extrusion process.

(2) To develop compounds or mixed plastics between thermoplastic starch and biodegradable polymers that are ready to be molded into biodegradable plastic products.

What did the research team do?

The research team has applied the knowledge of twin screw extrusion process by designing the screws, the melting process, and controlling the vacuum system for the water extraction to convert tapioca starch into thermoplastic starches, as well as the preparing process of mixed plastics or ready-to-use compounds. In the final step, the research team has demonstrated the preparation of thin film products by the blown film process.

Research results

- Knowledge of thermoplastic starch production processes and prototypes.

- Prototypes of mixed plastic pellets or compounds between thermoplastic starch and biodegradable polymers, and prototypes of biodegradable blow molding film due to the high content of starch.

Research status

The research result has been completed.

Outlook

The research team plans to apply the acquired knowledge and skill to further develop new formulas and products.

Research team

Dr. Noppadon Kerddonfag, Dr. Supanut Phattarateera and Mr. Pramote Kumsang

Contact

Mr. Chanit Wanikanukul (Senior Analyst)

Industrial and Business Liaison Section

Business Development Division

Tel. +66 2564 6500 ext. 4788

Email: chanitw@mtec.or.th