Executive Summary

The National Metal and Materials Technology Center (MTEC) operates its mission through a direction that is consistent and linked to the strategic plan of the National Science and Technology Development Agency (NSTDA) No. 7 (The Fiscal Year 2022-2027), which is also linked to the 20-year National Strategy Plan (2018-2037) and master plans at various levels, such as the strategy to drive national development with a bio-economic model, circular economy, and green economy (Bio-Circular-Green Economy: BCG Model) and the 20-year research and innovation strategy (2017-2036). MTEC places importance on taking advantage of the opportunities provided by the high technology infrastructure, especially "Eastern Special Economic Corridor of Innovation: The Innovation Infrastructure to Support Thailand 4.0" to create works that meet the needs of various sectors and apply research findings for practical use in resolving problems or developing business, thus, creating a significant positive impact on the economy and society.

Research, development and innovation to meet the needs of the country

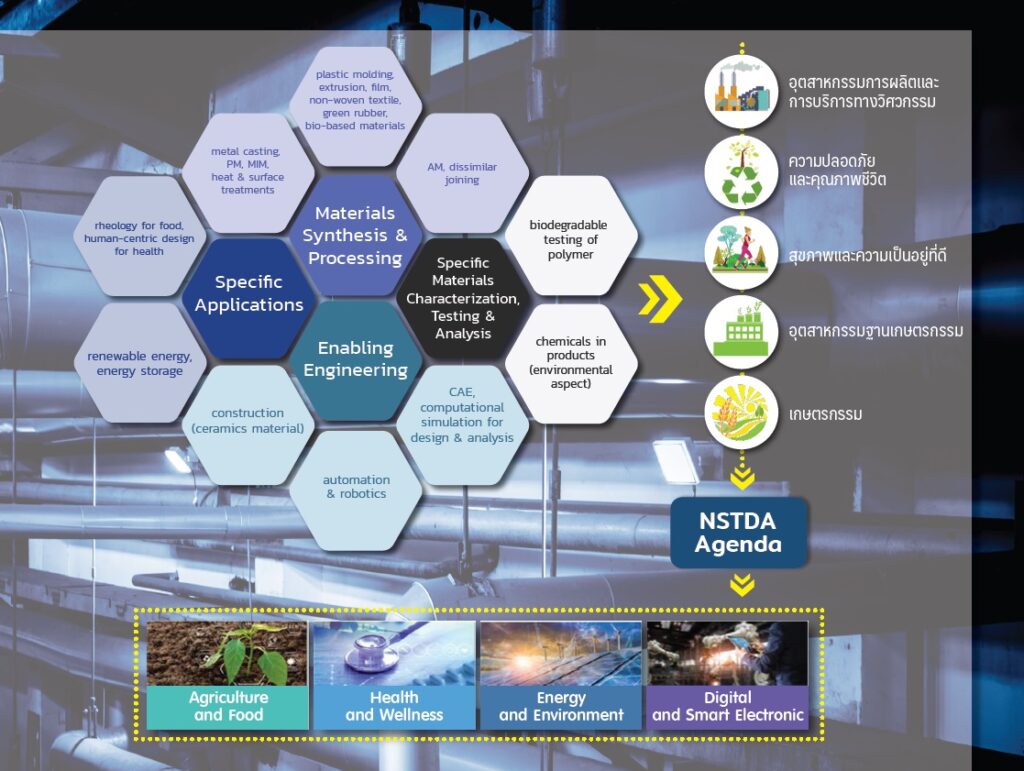

MTEC develops and builds capabilities in materials technology by using Technology/Research S-curves as a tool for research management, resource allocation, and work plan in order to deliver research outputs in various forms. For example, articles, prototypes and intellectual property are used for both commercial and public benefits through technology transfer mechanisms, research collaboration, and joint research, leading to impact and investment in economic and social aspects. MTEC has 5 main utilization target groups, namely manufacturing and engineering services industry, safety and quality of life, health and wellness, agro-base industry and agriculture. MTEC also focuses on the main point of Circular Economy, Health and Wellness that are national problems and set to be the national agenda, namely the BCG model (Bio-Circular-Green Economy) and the Industry 4.0 to enhance the competitiveness of the manufacturing and service industries.

Research Highlights and Industrial prototypes

Research Highlights:

- Reinforced Superstructure Design of Ambulance Van Patient Compartment

- Magik Growth

- Thermoplastic natural rubber traffic cones.

- Skill Preparation and Know-How Development in Designing and Manufacturing of Pick-Up Stay Side Steps from Plastic Composites

Industrial prototypes:

- Fabrication of Open-Cell Commercially Pure Titanium Foam using Slurry Impregnation Method

- Lightweight Aluminum Bus Structure

- Lateral Underrun Protective Device for Heavy Goods Vehicles

- Flexural Rigidity-Enhanced Ambulance Door

Outputs in business development and technology transfer

MTEC encourages close relation between its research and business development teams and the government and private sectors in order to utilize its research outputs in the industry and the general public. The key outputs are as follows:

- 8 commercial technology transferred to 8 organizations

- 5 technologies transferred to 8 organizations for public uses

- 405 projects are delivered, encompassing joint researches, contracts, consulting and standard testing service to

government and private sectors as follows: