Summary of the Seminar 📌 “Open Innovation for EV Battle: Thai Auto Parts Must Survive”

Thailand’s automotive industry is undergoing a major transformation as electric vehicles (EVs) gain momentum. In response to this shift, the seminar, titled “Open Innovation for EV Battle: Thai Auto Parts Must Survive,” convened key stakeholders from across the ecosystem—including entrepreneurs, government agencies, industry associations, and financial institutions. The event served as a platform to assess emerging challenges and collaboratively explore adaptive strategies to ensure the resilience and competitiveness of Thailand’s auto parts sector in the evolving EV landscape.

|

“We must build resilient networks of collaboration to turn this crisis into a springboard for industry renewal.”

— Dr. Sumittra Charojrochkul, Director of TECE and ENTEC, NSTDA

1. Transition Crisis: A Defining Challenge

The global automotive sector is undergoing its most rapid and disruptive transformation to date. Electric vehicles (EVs) are no longer a niche alternative—they now represent the dominant trajectory shaping the industry’s future.

Key challenges facing Thai manufacturers include:

- Electronics capability gap: While Thai firms excel in mechanical disciplines like bodywork, powertrain systems, and forming technologies, they lack in power electronics—an essential component of EV innovation.

- Fragmented entry into the EV supply chain: Fewer than ten Thai companies have penetrated the EV ecosystem, and their involvement remains limited and disconnected.

- Rising competition from Chinese manufacturers: Chinese players benefit from scale, advanced technology, and robust government backing, intensifying pressure on Thai firms.

Accelerated OEM timelines: Original equipment manufacturers now demand production cycles as short as 2–4 months, challenging local suppliers to adapt quickly.

|

“We must unite the strength of all sectors to tackle these challenges and become the wind beneath the wings of Thai entrepreneurs as they adapt and grow sustainably.”— Dr. Sarawut Lerspalungsanti, Deputy Director of TECE and MTEC, NSTDA

2. Strategic Transformation: From “Order Taker” to “Co-Creator”

Even in times of crisis, opportunities remain for those willing to adapt — and a mindset shift is the key to unlocking them.

Key strategies for successful transformation include:

- Shift from Make-to-Order to Make-to-Design: Redefine your role from passive

manufacturer to active co-developer and innovation partner.

- Develop electronic capabilities: Bridge the gap by building electronic skills that complement existing mechanical expertise.

- Explore blue ocean opportunities: Diversify into emerging industries such as rail systems, medical technology, and agricultural machinery.

- Accelerate Digital & Green Transformation: Leverage ERP platforms, robotic automation, and AI to boost productivity and reduce operational costs.

“The survival of auto parts manufacturers — and the livelihoods of over 700,000 workers — depends on collective action. I’m truly encouraged to see organization across sectors, along with the dedicated NSTDA team, joining forces to support Thai entrepreneurs every step of the way.”

— Mr. Supot Sukpisan, Chairman of the Auto Parts and Accessories Industry Group, The Federation of Thai Industries (FTI), and Deputy Secretary-General of the Thai Auto Parts Manufacturers Association (TAPMA)

“Developing talent in electronics and software is the cornerstone of a thriving EV industry.”

— Mr. Treepol Boonyaman, Deputy Director of the Thailand Automotive Institute

“Entrepreneurs should build on their existing strengths, expand their horizons, and seek new opportunities by stepping out of their comfort zone. Collaborating with research institutions or universities may take some adjustment at first, but once aligned, progress accelerates quickly.”

— Ms. Vachara Leegomonchai, Chief Executive Officer, C.L.P. Engineering Co., Ltd.

“To become a vendor for EV manufacturers, we must reduce costs, diversify models, and deliver within short timelines. NSTDA teams provide vital support in enhancing production capabilities and linking with government mechanisms.”

— Mr. Susayam Anantasainon, Director of Sales and Marketing, Thai Nam Plastic Public Co., Ltd.

3. Success Stories: Models of Effective Transformation

Learning from those who have successfully navigated industrial transitions offers powerful inspiration.

Outstanding examples of adaptation include:

- C.L.P. Engineering Co., Ltd.: The company evolved from producing aluminum die-casting automotive parts and brake systems to launching its own brand of post-harvest agricultural machinery, embedding smart technologies and IoT solutions.

- Thai Nam Plastic Public Co., Ltd.: Shifted from the Japanese automotive OEM supply chain to the Chinese electric vehicle (EV) ecosystem by pioneering seat designs that feature heat-reflective and ventilated systems.

“These success stories prove that Thai manufacturers can harness their existing expertise as a springboard for advancing into new technologies.”

“The BOI has launched measures to safeguard existing production bases and, for the first time, established local content criteria for EVs and electrical appliances.”

— Ms. Yordkamon Suthirapojn, Senior Investment Promotion Officer, Office of the Board of Investment (BOI)

“PMU will provide comprehensive and robust support to enhance the competitiveness of the private sector.”

— Assoc. Prof. Dr. Pathomtat Chiradeja, Chair of the Program Management Committee for the Transportation, Logistics, Energy, Chemical and Biobased Materials, and Circular Economy Cluster, Program Management Unit for Competitiveness (PMUC)

“NIA accelerates market-ready research, with a focus on the EV sector—advancing key components, platforms, and specialized vehicles.”

— Ms. Pitcharee Keeratithakul

, Senior Innovation Development Officer, National Innovation Agency (Public Organization) (NIA)

“ITAP serves as a strategic intermediary, guiding entrepreneurs in shaping concept projects and building readiness ahead of funding applications.”

— Dr. Nantiya Viriyabanthorn, Director, Innovation and Technology Assistance Program (ITAP), NSTDA

4. Supportive Ecosystem: The Power of Government Synergy

Multiple government agencies have joined forces to establish Open Innovation platforms that empower Thai entrepreneurs not only to survive but to grow and thrive together.

Key support mechanisms include:

- Thailand EV Center of Excellence (TECE), NSTDA: Empowers entrepreneurs by linking them to knowledge, technology, innovation, and funding sources.

- Program Management Unit for Competitiveness (PMUC): Funds research projects at TRL 4–8, emphasizing private-sector collaboration and real-world application.

- National Innovation Agency (NIA): Delivers a wide range of support—from grants and market validation to low-interest loans—covering up to 75% of project costs.

- Board of Investment (BOI): Incentivizes investment through 3–8 years of tax exemption and targeted SME measures, while advancing local content in 17 key automotive components.

- Innovation and Technology Assistance Program (ITAP), NSTDA: Catalyzes Innovation by bridging entrepreneurs with industry experts to solve technical challenges and accelerate development.

5. Infrastructure and Human Resource Development: The Foundation of Transformation

Enhancing human potential alongside technological advancement is vital to driving a successful transition toward the future of the automotive industry.

Key development priorities include:

- Workforce upskilling: Emphasize electronics and software integration with existing mechanical systems. The Ministry of Higher Education, Science, Research and Innovation (MHESI), and partner networks are designing and delivering tailored training programs to meet industry demands.

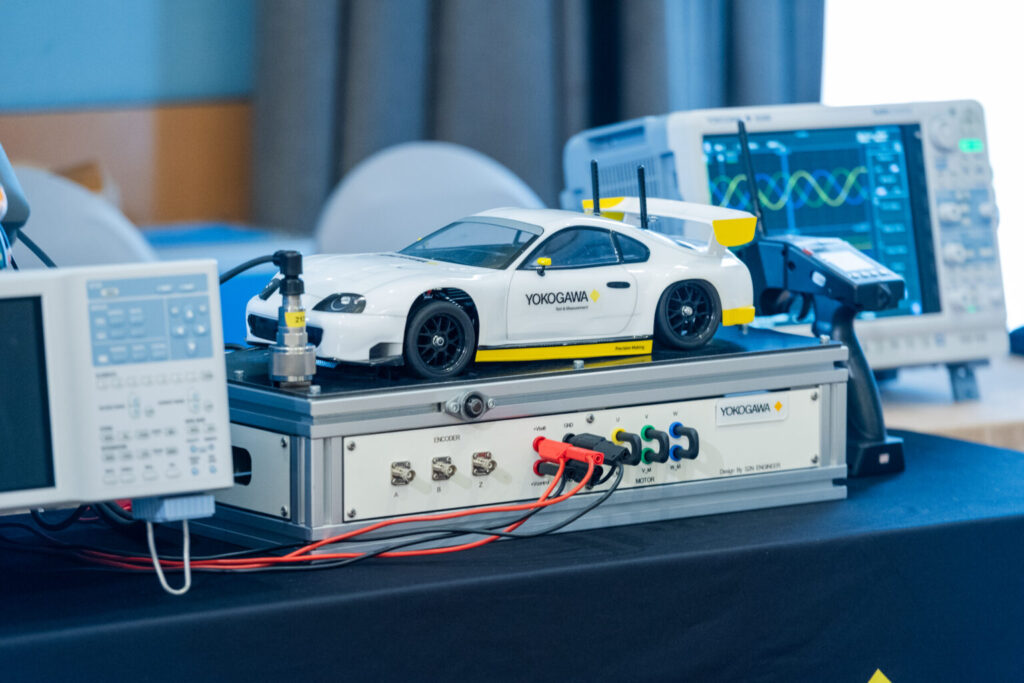

- R&D infrastructure: NSTDA deploys expert personnel and equips advanced testing facilities—such as the Hardware-in-the-Loop (HIL) system — to validate and refine battery management systems (BMS).

- Standards and certification: Function as critical enables strengthen reliability and sustain global competitiveness.

- Academic–industrial collaboration: Aligns academic expertise with industrial needs to accelerate commercialization and real-world applications.

Summary

The transition to the EV era demands broad-based collaboration across sectors, rapid adaptation, and strategic use of existing strengths to forge new capabilities. This approach seeks to transform challenges into opportunities and drive sustainable growth in Thailand’s automotive industry. The seminar reflected stakeholders’ deep awareness and strong commitment to guiding the industry through this pivotal shift toward resilience and long-term sustainability.