On December 17, 2024, the National Metal and Materials Technology Center (MTEC), led by Dr. Sitthisuntorn Supothina, Deputy Director, participated in the closing session of the “End-of-Waste (E-o-W) Criteria Development Project” at the Eastin Grand Hotel Sathorn, Bangkok.

During a year-long study, the project developed innovative processes to repurpose discarded plaster molds into gypsum wallboards and convert rice husk ash into bio-sodium silicate and bio-potassium silicate, advancing sustainable industrial practices. The event was presided over by Mr. Sunthron Kewsawang, Deputy Director-General of the Department of Industrial Works (DIW) and Vice-Chairman of the Technical Working Group (TWG) on Industrial Waste Utilization and Green Industry Development. Ms. Sirakarn Leungsakul, Director of the Environmental Technology Promotion Division at DIW, presented the project’s objectives.

A diverse panel of experts participated in the seminar, including Mr. Chulapong Taweesri, Advisor to the Minister of Industry; Ms. Pattamawan Khunprasert, Director of the Eco-Industrial Development Division; Mr. Eakbout Utamapong, Acting Senior Scientist at the Industrial Safety Technology Promotion Division of DIW; Dr. Uma Wirutsakulshai, UNIDO’s National Project Coordinator of UNIDO in Thailand; and representatives from government, academia, and industry.

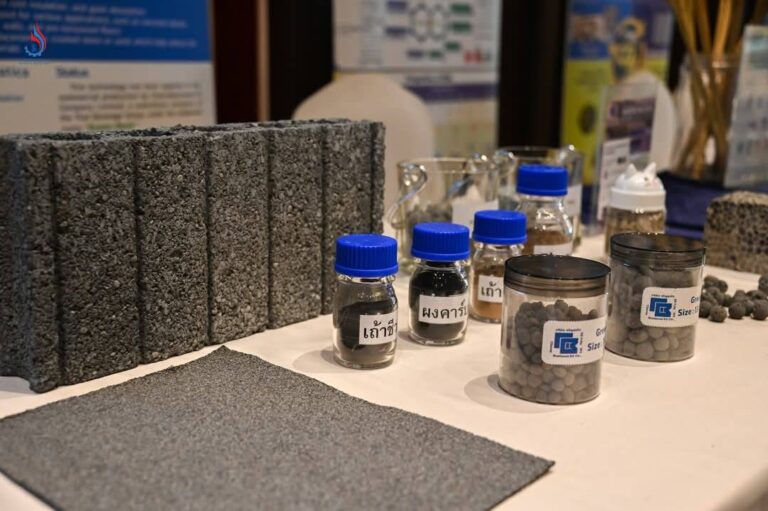

To facilitate the valorization of industrial waste into new raw materials or products, DIW conducted a study aimed at establishing end-of-waste criteria. The pilot study investigated four specific waste streams: 1) discarded plaster molds, 2) rice husk ash, 3) tuna fish bones, and 4) synthetic gypsum.

As part of the project’s research efforts, the Center of Excellence on Hazardous Substance Management at Chulalongkorn University investigated the repurposing of discarded plaster molds for gypsum wallboard in construction. Simultaneously, MTEC studied the feasibility of using rice husk ash in bone china ceramic production.

By transforming industrial waste into reusable materials or products under the end-of-waste concept, these efforts contribute to a comprehensive circular economy. This model incorporates key aspects such as raw material management, production processes, product applications, carbon dioxide emission calculations, technical feasibility, investment potential, and economic viability.

Research findings aid users in selecting waste-derived raw materials or products. End-of-waste criteria include: (1) the material or product must have a specific purpose; (2) there must be a clear market demand or established usage; (3) usage must comply with all applicable laws, regulations, and standards; and (4) the usage must not pose any risk to human health or the environment.

The seminar featured a panel discussion, “Lessons Learned from (Draft) End-of-Waste Criteria Development and Future Policies for Industrial Waste Management,” where stakeholders shared their insights and recommendations for improving end-of-waste criteria. DIW will compile study results, feedback, and expert suggestions to enhance policy guidelines for Thailand.