On September 4, 2025, at the Press Conference Hall, Ground Floor of the Yothee Research Building, NSTDA, Rama VI Road, Ratchathewi District, Bangkok,

The National Metal and Materials Technology Center (MTEC), under the National Science and Technology Development Agency (NSTDA), hosted the “NSTDA x Press Interviews” event themed “Design for Circular Economy: Think Before Making Moves – The Key to Building Sustainable Business.”

The event featured an insightful discussion led by Dr. Witchuda Daud, a Researcher at MTEC, NSTDA, alongside Mr. Auychai Siriwojana, Director of Tirathai Public Company Limited, and Mr. Thitipun Vanichtanasri, an Executive at PSM Plastitech Group. Together, they explored how circular design principles can be effectively applied to drive corporate sustainability and reshape business models for long-term impact.

“Thinking from the Beginning” — The Core Principle of Circular Design

“Thinking from the Beginning” — The Core Principle of Circular Design

Dr. Witchuda Daud, a researcher from the Plastic Technology Research Team under the Advanced Polymer Technology Research Group at MTEC-NSTDA, explained that the concept of Design for Circular Economy centers on integrating sustainability from the very beginning of the product development process. It involves proactively identifying strategies to extend product lifespan and preserve resource value for as long as possible. Rather than following the traditional “make–use–dispose” model—which contributes to waste accumulation and environmental harm—product should be designed to enable multiple lifecycles through repair, reuse, recycling, or energy recovery.

She emphasized that the heart of circular design lies in forward-thinking: planning for material recovery and reuse from the outset, rather than reacting to waste after it occurs. In today’s landscape, sustainability has become a critical imperative for Thai industries, which are grappling with rising production costs, limited expertise in materials and product design, outdated machinery that must be adapted for new materials, challenges in building market trust, and the absence of a fully integrated waste-management infrastructure.

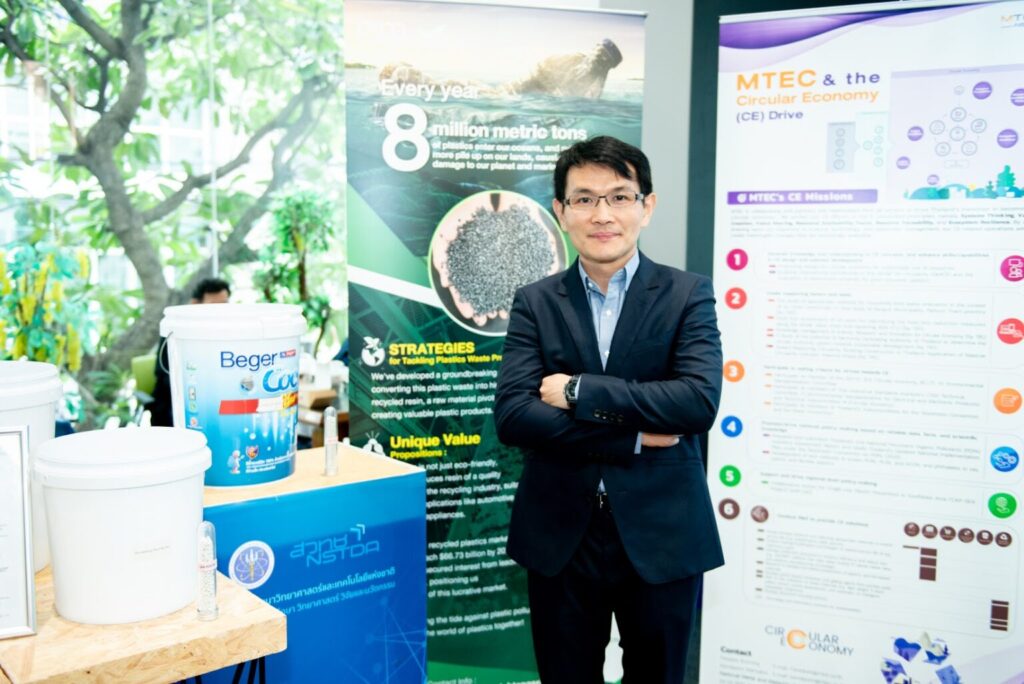

To help address these challenges, MTEC-NSTDA has taken on the role of an “innovation mentor,” guiding Thai entrepreneurs in adopting circular design principles through targeted initiatives. Among these is the Design for Circular Economy Project, which promotes the sustainable use of mineral and metallic resources, supported by the Department of Primary Industries and Mines (DPIM), Ministry of Industry.

Dr. Witchuda Daud asserted that within the next five years, “Made in Thailand products” will evolve to become more sustainable and eco-friendlier, with increased focus on leveraging renewable resources and easily recyclable materials, as well as designs that enable disassembly, repair, and upgrading to reduce waste and extend product life.

Future manufacturing systems, she clarified, will be engineered to facilitate seamless information transfer throughout a product’s life cycle. For example, the adoption of Digital Product Passports (DPP) will empower detailed tracking of material types, components, disassembly methods, maintenance procedures, and end-of-life management guidelines. This information will streamline access for recyclers and subsequent manufacturers to recover and maximize the use of resources.

Such a transition, Dr. Witchuda emphasized, demands collaboration across all sectors. The public sector should formulate policies and standards for the Circular Economy while supporting R&D and transparent data systems. The private sector must commit to innovation, transform production processes, and develop products based on circular principles. Meanwhile, consumers play an equally crucial role by selecting sustainable products and managing resources responsibly. If all three sectors mobilize today, Thailand will be able to produce goods that optimize resource use, thrive sustainably, and excel on the global stage.

“Circular Economy is the Future — Thai Entrepreneurs Setting New Global Standards”

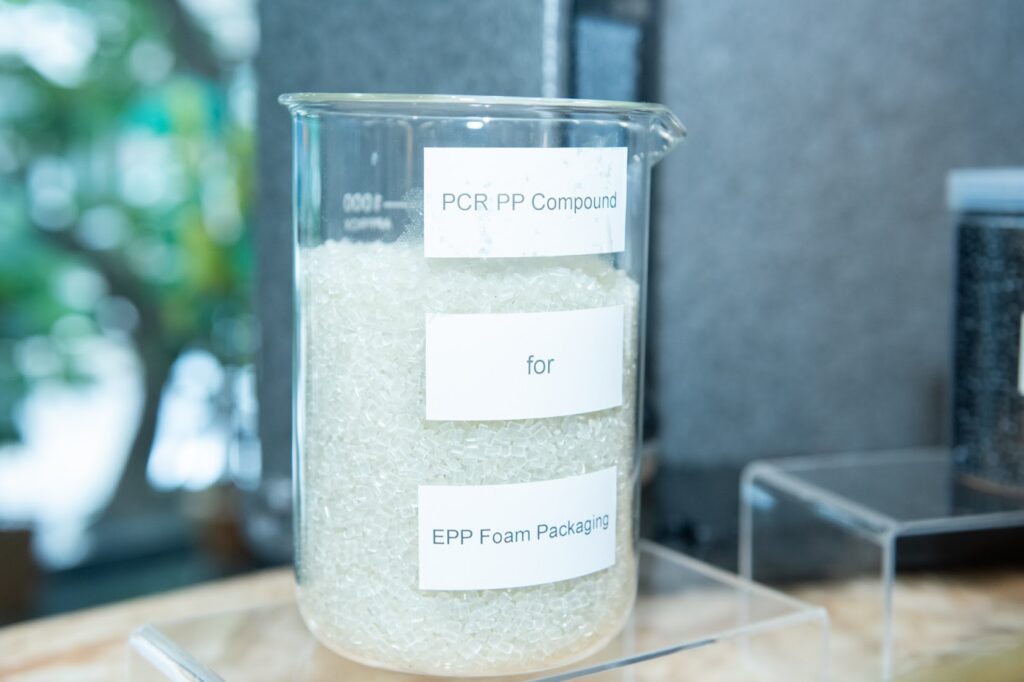

Mr. Thitipun Vanichtanasri, Executive of PSM Plastitech Group, outlined his vision to convert used plastics into valuable resources rather than waste by pioneering innovative recycling processes from the very beginning. The company has successfully engineered recycled plastic pellets with properties equivalent to 80% of virgin materials, making them suitable for use in high-standard industries such as automotive, electrical appliances, and packaging.

The company’s key strength resides in its requirement-driven production process, which originates with customer needs and fosters close collaboration with factories, brand owners, and communities to categorize and refine raw materials that meet Global Recycle Standard (GRS) certification, guaranteeing full traceability at every stage.

Furthermore, PSM Plastitech’s recycled plastic pellets significantly help reduce greenhouse gas emissions, with a carbon footprint of only 0.3–0.45 kg CO₂ per kilogram, much lower than the 1.8 kg generated by virgin plastic pellets. This achievement reflects global market trends that emphasize sustainability and environmental responsibility.

Mr. Thitipun further stated that the company’s success stems from its collaboration with MTEC-NSTDA, which serves as a “mentor,” offering extensive knowledge and technical assistance in Design for Circular Economy—encompassing product design and comprehensive chemical analysis of plastics. This partnership has facilitated the company’s evolution from solely a raw material supplier to a product development consultant compliant with international environmental standards, especially the rigorous requirements of Europe, Japan, and South Korea, which prioritize recycled material ratios and carbon footprint reduction.

Besides its economic contribution, the company also benefits society and the environment by providing income to local communities through plastic waste sorting and helping to prevent waste from leaking into the ocean, one of Thailand’s urgent environmental problems.

Mr. Thitiphan concluded by reaffirming the company’s goal to raise public awareness that used plastics can be truly transformed into new value when managed through a proper, standardized system, thereby driving Thailand’s recycling industry toward a sustainable future.

Mr. Auychai Siriwojana, Director of Tirathai Public Company Limited, affirmed that over its 39 years of operation, the company has established itself as a leading expert in manufacturing all types of power transformers, ranging from small units to high-voltage systems up to 525 kV, with a firm commitment to continuously enhancing Thailand’s electrical energy standards.

In collaboration with MTEC-NSTDA, Tirathai has introduced the Remanufactured Transformer, an innovation that revives used transformers to as-new quality, meeting 100% of international testing standards. This project marks a significant milestone in advancing Thailand’s Circular Economy, as transformers are products that require substantial resources. By remanufacturing over one million used transformers across the country, the initiative helps preserve raw materials, reduce pollution, lower carbon footprints, and generate economic value exceeding tens of billions of baht.

The company prioritizes establishing quality standards to guarantee that remanufactured transformers are safe and recognized internationally. Support from MTEC-NSTDA, especially in accurate assessment and quantification of carbon footprints, is instrumental in propelling Thailand toward a truly sustainable Circular Economy system.

Mr. Auychai noted that this represents an important step towards creating a clean and safe energy future for Thailand. The company remains dedicated to advancing energy technologies and encourages the industrial sector to adopt Circular Economy (CE) transformers, aiming to lower carbon emissions and protect the environment through collaborative efforts.

The progress toward a Circular Economy has been driven by MTEC-NSTDA’s crucial role as an “innovation mentor,” delivering knowledge in Design for Circular Economy, technical analysis, and the development of international standards for Thai entrepreneurs.

Collaboration with PSM Plastitech Group has led to the production of recycled plastic pellets with properties up to 80% equivalent to virgin materials, while cutting greenhouse gas emissions by as much as 75%. Meanwhile, the partnership with Tirathai Public Company Limited has resulted in the development of remanufactured transformers that create tens of billions of baht in economic value from existing resources.