On September 11, 2025 at the National Defence College of Thailand, the student cohort of the National Defence College, Class 67 (Wor Por Or 67), formally handed over the “Prototype Modified Excavator for PMN-2 Landmine Clearance in Highly Complex Border Areas” to Lt. Gen. Siraphop Supphavanich, Chief of the Royal Thai Army’s Corps of Engineers, for deployment in national defense missions.

Maj. Gen. Sadet Akachak, President of the National Defence College Class 67, explained that in recent years, during periods of border tensions between Thailand and Cambodia, Thai soldiers tasked with border protection have frequently encountered PMN-2 landmines planted by Cambodia, especially along patrol routes. These incidents have resulted in serious injuries and the loss of limbs among Thai troops. To address this, NDC Class 67 utilized the ideas, capabilities, and networks of its members, collaborating with the Royal Thai Army’s Corps of Engineers (Mine Warfare Division) to identify strategies that could shield and support the fighting force against this specific threat.

He added that the project was carried out in collaboration with the National Science and Technology Development Agency (NSTDA), a public agency under the Ministry of Higher Education, Science, Research, and Innovation. NSTDA collaborated with the team to design and develop the modified excavator for PMN-2 landmine clearance as a prototype specifically engineered to navigate narrow paths and complex terrain, and to apply force to neutralize PMN-2 explosive devices. The machine is intended to serve as a vital tool for small patrol units operating in suspected or high-risk areas, thereby helping to reduce potential harm and enhance the safety of both civilian and military personnel.

Today, the NDC Class 67, together with NSTDA, is honored to officially hand over this prototype machine to the Royal Thai Army’s Corps of Engineers for field deployment. Regarding the blueprint and technical design, NSTDA is prepared to provide comprehensive support should there be interest in further production or development.

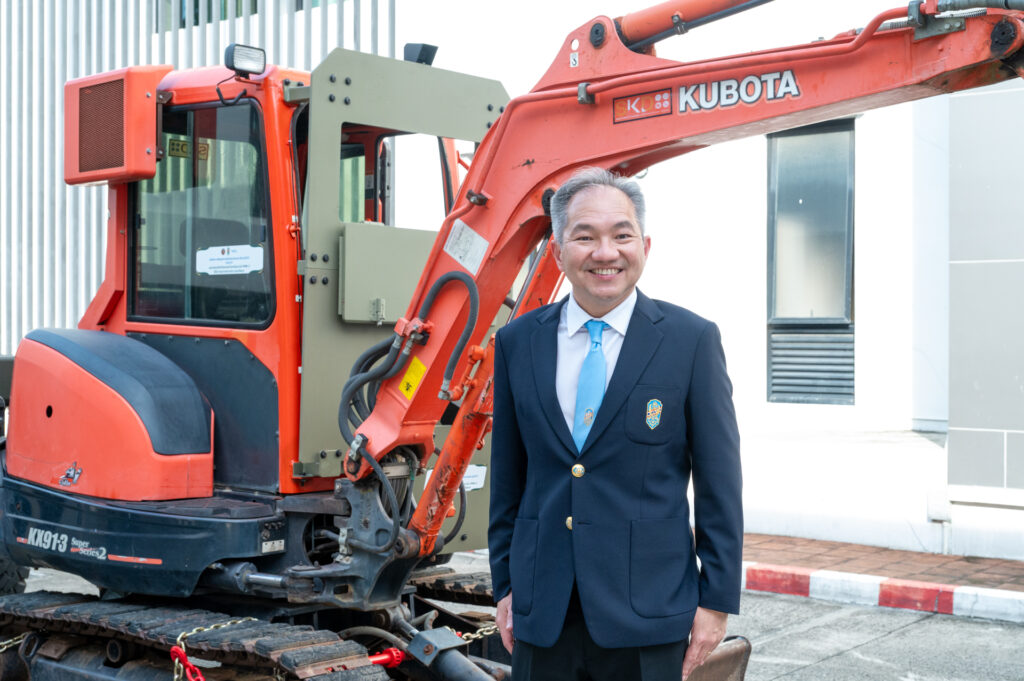

Prof. Dr. Sukit Limpijumnong, President of the National Science and Technology Development Agency (NSTDA) and a member of NDC Class 67, added that, “NSTDA, through the National Metal and Materials Technology Center (MTEC), with support from the NDC Class 67 cohort, has developed the prototype landmine-neutralization machine. The project was spearheaded by Dr. Ekkarut Viyanit, Director of the Rail and Modern Transport Technology Research Group (RMT), who oversaw the advanced engineering design and material technologies utilized for neutralizing PMN-2 landmines.

The innovation began with the concept of modifying a compact excavator (approximately 3.5 tons), which was selected for its maneuverability on steep, rugged terrain, ease of operation, and durability. The excavator was subsequently fitted with a landmine-neutralizing attachment and reinforced with an armored operator cabin, thus ensuring personnel remained protected during operations.

Advanced engineering design, incorporating 3D modeling and computer simulation, was applied to engineer the machine components with precision, thereby ensuring dimensional accuracy for fabrication and adequate structural strength to withstand explosive pressure. The team also analyzed blast-pressure behavior that could pose risks to operators, using computer-based simulations to study potential human hazards.

Given MTEC’s extensive experience with high-strength materials, the protective armor for the operator cabin was fabricated from S700 structural steel (minimum yield strength of 700 MPa) with a thickness of 12 mm. The newly designed Landmine Punching Destroyer unit was developed specifically to meet the operational requirements for PMN-2 neutralization. The ‘punch rod’ was engineered with an optimal standoff distance from the ground surface to dissipate blast pressure and reduce the potential for rapid component damage. The rod is made from medium-carbon steel, heat-treated for sufficient strength (yield strength of 720 MPa), and manufactured as a threaded stud bolt with a 28.5 mm diameter, thereby allowing easy removal, replacement, or repair during field operations along the border.

The prototype was successfully completed within a short development period of just one month and is now ready to be handed over to the Royal Thai Army’s Corps of Engineers for field testing and evaluation. Real-world use will enable the research team to collect feedback and operational data, which will guide improvements and inform the development of future versions.”

This innovation demonstrates that NSTDA’s work extends beyond the laboratory, applying research to address tangible national challenges. The development of a tool engineered and built by Thai experts to support national security is a great source of pride, helping to improve safety for both the populace and the land along the border.