Research and Development Directions

MTEC’s operations are aligned with and linked to the strategic plans of the National Science and Technology Development Agency (NSTDA) version 7.1 (fiscal year 2023-2027), which is in turn connected to the 20-Year National Strategy for 2018-2037. This includes various master plans, such as the Bio-Circular-Green Economy (BCG Model) for driving the country’s economic development, and the 20-Year Research and Innovation Strategy (2017-2036).

MTEC emphasizes using opportunities from high-level technological infrastructure, particularly the “Eastern Economic Corridor (EEC) Innovation Zone: Innovative Infrastructure to Support Thailand 4.0” initiative. This initiative aims to generate outputs that meet the needs of various sectors and utilize research outcomes to address challenges or improve businesses, leading to significant positive impacts on the economy and society.

Working Strategies

MTEC focuses on the four pillars of excellence:

1. Excellence: Achieving exceptional outcomes through unwavering dedication and unparalleled expertise.

2. Relevance: Fostering synergy between national priorities and user aspirations.

3. Impact: Driving economic growth, enhancing well-being, and strengthening competitiveness through research, development, and engineering.

4. Visibility: Establishing a reputation for excellence and expertise that transcends borders.

At the forefront of innovation: MTEC’s research initiatives span a broad spectrum of domains, encompassing technology material development, design, manufacturing technology application, developing essential infrastructure for national progress, and interdisciplinary research to address critical national challenges. MTEC is also committed to enhancing knowledge and capabilities to adapt to rapid technological changes, ensuring that Thailand remains at the forefront of innovation.

Operation Mechanisms

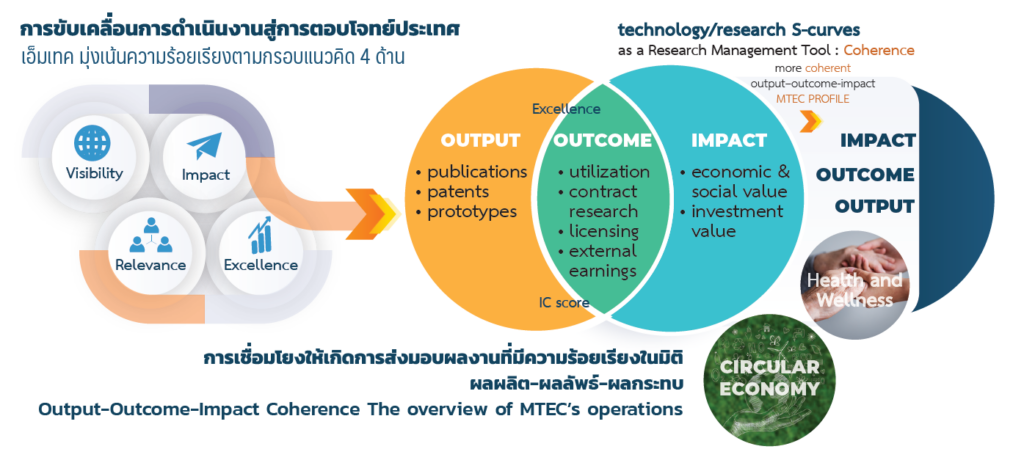

MTEC employs a systematic and continuous operational mechanism by crafting technology development plans, instigating research initiatives, and devising delivery strategies. It harnesses the power of Technology/Research S-curves to guide research management, resource allocation, and work planning. MTEC prioritizes aligning research plans with national strategies and tackling pressing national challenges, fostering knowledge and capabilities to navigate the ever-evolving technological landscape.

Transforming research into real-world impact: MTEC delivers research outputs in various forms, including articles, prototypes, and intellectual property, which are then translated into tangible outcomes. These outcomes are leveraged for commercial and public benefit through technology transfer, contract research, and collaborative research efforts, creating a ripple effect of impact and investment opportunities in economic and societal contexts. MTEC’s focus spans five main target areas: engineering manufacturing industries, safety and quality of life, health and wellness, agricultural and agribusiness industries, and Circular Economy. This includes addressing national challenges such as the Bio-Circular-Green Economy (BCG) Model and Industry 4.0 to enhance the competitiveness of manufacturing and service industries.

The shift in research budget allocation from direct allocation from the budget office to the National Science, Research, and Innovation Fund (NSRF) in 2020 has challenged MTEC’s traditional funding approach. To adapt, MTEC has implemented research management processes that align with external funding sources and the country’s research budget system. By actively establishing research networks with domestic and international partners, MTEC is developing collaborative research agendas and identifying opportunities to secure funding for large-scale projects. Additionally, MTEC is streamlining its internal management processes, particularly in research management support, to ensure agility in responding to dynamic circumstances and achieving the organization’s objectives.”

In 2023, MTEC has emerged as a driving force behind critical initiatives in Circular Economy, Health and Wellness, and Industry 4.0, which are national priorities. MTEC is steadfastly dedicated to generating a continuous stream of high-impact outcomes that empower and elevate the competitiveness of diverse industries and sectors.

Circular economy

In the realm of Circular Economy, MTEC has spearheaded strategic collaborations with funding bodies and network partners, both domestically and internationally, to orchestrate initiatives that drive the transformation of industries toward a circular economic paradigm. This transformation demands a holistic approach that encompasses product design, manufacturing processes, and business models.

Illustrative examples of pivotal initiatives in the domain of Circular Economy encompass:

- Special Lectures for Entrepreneurs and Circular Economy Enthusiasts: Hosting a special lecture titled “Circular Economy and Resource Efficient and Effective Solutions” on January 19, 2023.

- Practical Training Programs: Conducting hands-on training sessions under the intensive course “Arming Thai Industries with Circular Economy Design Season 2” on March 13, 27, April 4, 21, and 28, 2023.

- Circular Economy Talks Seminar: Organizing the “Circular Economy Talks: From Vision to Development” seminar as part of the 18th NSTDA Annual Conference (NAC 2023) on March 30, 2023.

- Design Solution Challenge: Initiating the Design Solution 4 Circular Economy Challenges Season 2″ from April to September 2023, aimed at developing solutions based on Circular Economy principles.

- Collaboration with Environmental Foundation: Signing a memorandum of understanding with the Thai Environmental Foundation for “Environmental Impact Assessment of Certified Environmental Labels for Products”.

- Research and Development Partnership: Collaborating to research and develop ways to add value to industrial waste by turning it into raw materials or new products to achieve “End of Waste” status.

Promote health and Well-being

In the realm of health promotion and well-being, MTEC has cultivated robust synergies with local partners and funding bodies within Thailand. These include Health Systems Research Institute (HSRI), the Office of the Thailand Science Research and Innovation (TSRI), the Office of Program Management Unit for Competitiveness (PMUC), and a network of esteemed hospitals.

Compelling illustrations of tangible contributions in the real world encompass:

- Gunther Bath: In-wall fall detection and alerting system innovation.

- Rachel: Exosuit – aiding mobility and injury prevention for the elderly

- Ross – Back Support model: Exosuit technology assists in mobility and injury prevention for caregivers of patients/elderly individuals.

- Simulated breast platform: a precision training tool for disease diagnosis using ultrasound and tissue biopsy.

- Custom insole and spinal support equipment manufacturing system using 3D printing technology for individuals.

- “Ve-Sea” food product line: Plant-based fish ball and plant-based seafood products, etc.

Throughout 2023, MTEC hosted a series of events to showcase its innovative projects, including seminars, innovation launches, and consecutive exhibitions. These events highlighted more than 15 groundbreaking initiatives, including the introduction of the ‘Exosuits’ innovation series named ‘Rachel’ and ‘Ross’ on March 31, 2023, and a press conference on July 3, 2023, to unveil a new innovation series focused on the separation and movement of patients in response to emerging and recurring infectious diseases.

Industry 4.0

Research and development geared towards Industry 4.0 is a crucial aspect that MTEC utilizes to apply knowledge, support, and elevate various industries.

Some examples of achievements in the field of Industry 4.0 include:

- Development of industrial automation solutions for manufacturing processes.

- Development of automation systems for agricultural machinery.

- Development of autonomous robots for various applications.

MTEC’s pioneering industrial breakthroughs in 2023 created transformative impacts across the public and private sectors. Among these advancements are an System Prototype Wet Ash Monitoring on Submerged Scraper Conveyor (SSC), Slag Deposition Sensor, and Lightweight structural parts for high performance electric scooter.